THE TECHNOLOGY

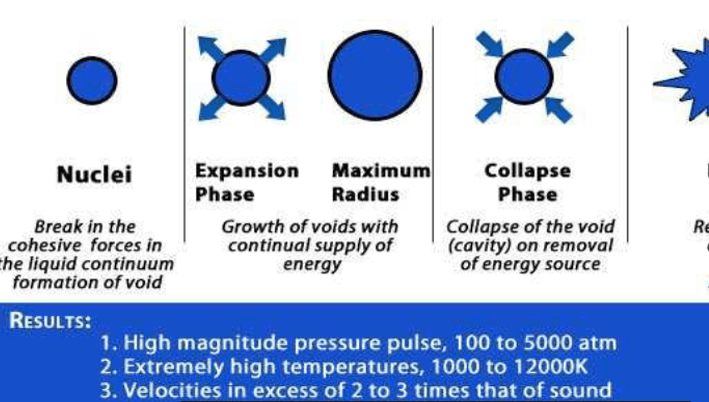

Decreasing the pressure over a liquid and bringing it to its vapor pressure at the operating temperature generates vapor bubbles in the liquid. When the pressure is brought back to normal pressure, these vaporous bubbles collapse with a bang to generate intense pressure and temperature at the point of collapse (Fig. 1). Such intense conditions (5,000 atm and 12,000°K, intense turbulence) and resulting shock wave can bring about several physical, chemical & biological transformations, even when the bulk conditions are ambient.

EnviroTech Technology uses this technology to create and collapse precisely tailored cavitation bubbles to modulate the pressure, temperature, and turbulence conditions by means of controlled variations in the pressure of fluid.